Technology Decoded: Steering Gear & Types

Modified On Mar 16, 2016 04:19 PM By Sahib

- Write a comment

Steering gear boxes not only steer the front wheels, but also play an important role in reducing the effort which goes into steering the steering wheel by an equivalent increment in the output torque. The gear setup used in this mechanism is of different types, depending upon the output required.

Technology Explained:

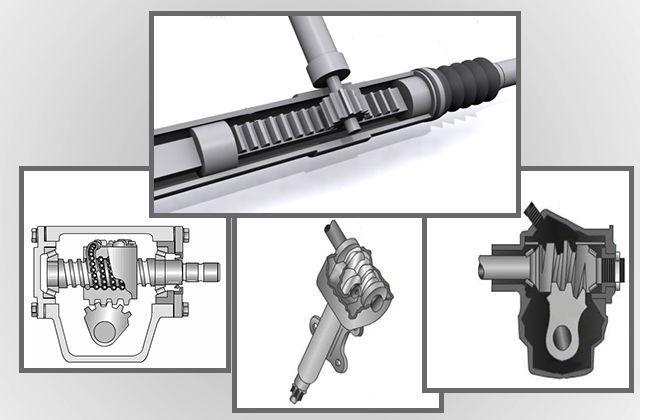

The type of steering gear which is to be deployed depends on the method of coupling the steering tube with the cross-shaft. Various types of steering gears are:

1. Rack and Pinion type Steering Gear:

In this system, steering column has a pinion at its bottom end. The teeth of the pinion is made to mesh with teeth on the rack. The end of rack is connected to the stub axle through a rod. As the pinion rotates, it forces rack to move in left and right direction, which in turn operates the stub axle.

2. Worm and Roller Type Steering Gear:

In this gear setup, roller (usually 2 toothed) is fastened to the cross shaft. At the end of steering tube there is a worm gear, which meshes with the roller. As the steering wheel turns, the worm rotates with it, which in turn brings the roller in motion, forcing the sector and pitman arm shaft to rotate.

3. Worm and Sector Type Steering Gear:

Its design is the same as basic worm and roller type steering gear box, except that roller is replaced by a sector. Worm at the end of the steering shaft mesh with a sector mounted on a sector shaft and accordingly provides the required gear ratio.

4. Re-circulating Ball type Steering Gear:

It involves a nut with steel balls acting as a thread. The rotation of the worm gear causes the balls to roll in the worm gear. This causes the ball nut to move up and down along the worm. Balls continuously recirculate through a pair of ball return guides from one end of the ball nut to the other. This design helps in reducing friction between worm and nut members.

5. Cam and lever Steering Gear:

In this, a special worm called cam replaces the conventional worm in steering gear box. It is cylindrical in shape and its actuating part is a groove of variable pitch. There are two studs mounted in bearings on the lever which engage the cam. Studs move up and down on the cam as the steering wheel is operated, which further causes the lever and pitman arm shaft to rotate.

6. Worm and Peg Type Steering Gear:

A cone shaped peg travels along the worm gear as the steering shaft is rotated. Peg is mounted on a lever which in turn drives the drop arm (pitman arm) via a shaft.

Steering Gear Ratio: It indicates number of turns on the steering wheel required to produce one turn of the steering-gear cross shaft to which the pitman arm is attached. Higher the steering ratio, more the steering wheel has to be turned to achieve desired steering. Therefore, high steering gear ratio produces slow steering, while low ratios produces fast steering. The ratio normally varies between 14:1 and 24:1.

Also Read: Technology Decoded: Steering System

1 out of 1 found this helpful